Prototyping in Product Development

In the fast-paced world of product development, effective prototype development can make all the difference between a successful launch and a costly misstep. As businesses strive for innovation, understanding various prototyping techniques is crucial. This blog post delves into essential prototyping methods, including 3D printing, urethane casting, sheet metal forming, CNC milling, and lathe machining. By iterating on designs using 3D CAD and quickly validating prototypes, companies can significantly enhance their industrial design and product engineering processes.

Why Prototyping Matters in Product Design

Prototyping serves as a bridge between concept and reality. It allows designers and engineers to visualize ideas, test functionality, and identify flaws before mass production. Each prototyping technique brings its own set of advantages that cater to different stages of product design.

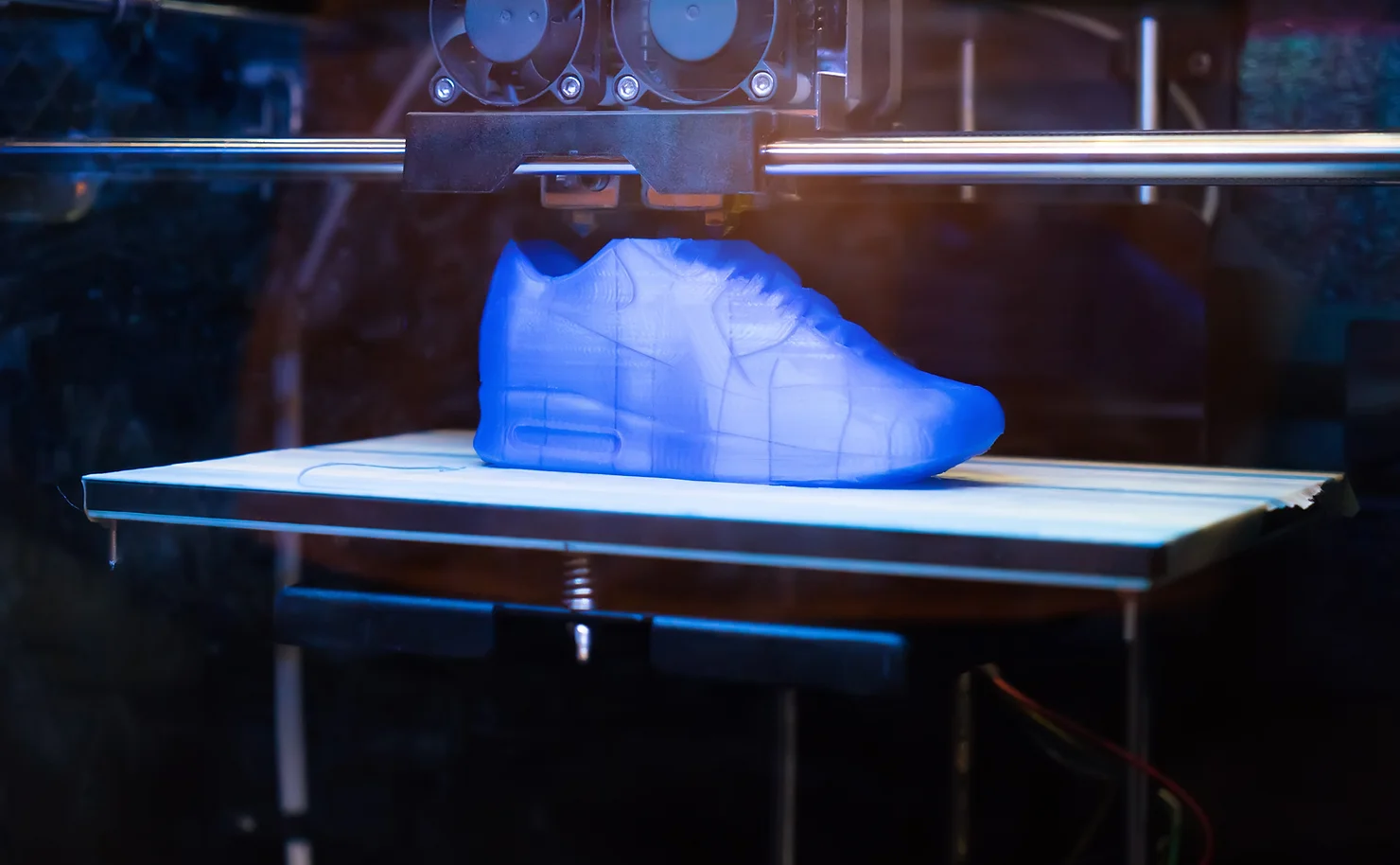

1. 3D Printing: Rapid Prototyping Revolution

3D printing is one of the most popular methods in modern product development. It enables rapid prototyping, allowing designers to create complex geometries with ease. This technology facilitates quick iterations, helping teams visualize their concepts and test them almost instantly. The ability to modify designs in 3D CAD and produce a physical prototype within hours accelerates the validation process and shortens development cycles.

2. Urethane Casting: Cost-Effective and Versatile

Urethane casting offers a great balance between cost and quality, making it ideal for low-volume production runs and detailed prototypes. This method is particularly beneficial for testing various materials and finishes before settling on a final design. Unlike 3D printing, urethane casting can replicate the look and feel of production materials, providing more accurate insights into how the product will perform in the real world.

3. Sheet Metal Forming: Precision and Efficiency

For products that rely heavily on metal components, sheet metal forming is invaluable. This technique allows for the creation of precise parts that can be tested for fit and function. The ability to create prototypes that closely mimic final products is essential for validating designs, especially in industries like automotive and aerospace. By leveraging sheet metal forming, engineers can ensure their designs meet stringent industry standards.

4. CNC Milling: High Precision and Complexity

CNC milling is perfect for creating intricate and high-precision components. This method is particularly useful for functional prototypes where accuracy is paramount. The precision offered by CNC milling allows for comprehensive testing of mechanical functions and tolerances. Furthermore, CNC machining can be employed on a variety of materials, making it a versatile choice for many product engineering projects.

5. Lathe Machining: Turning Ideas into Reality

Lathe machining is another essential prototyping technique, especially for cylindrical parts. This method allows designers to produce high-quality prototypes quickly, enabling rapid iterations and testing. Whether it’s a simple shaft or a complex housing, lathe machining can provide the necessary precision to ensure that parts fit together seamlessly.

The Importance of Testing to Failure

A critical aspect of effective prototyping is testing to failure. While simulation offers valuable insights, real-world testing often reveals unexpected issues. Prototyping allows teams to push their designs to the limits, uncovering flaws that simulations might overlook. This approach is not only more insightful but often more cost-effective than relying solely on digital models. By identifying weaknesses early in the development process, teams can avoid costly redesigns later on.

Iterative Design and Quick Validation

The ability to iterate on designs in 3D CAD software is a game-changer in product design. Teams can quickly create and modify prototypes, enabling a fast-paced environment of innovation. This rapid iteration and validation cycle allows companies to respond swiftly to feedback, ensuring that the final product meets customer expectations and industry standards.

Conclusion

Incorporating various prototyping techniques into your product development process is essential for success. From 3D printing to CNC milling, each method offers unique advantages that can streamline design iterations and enhance product quality. By embracing a culture of testing to failure and utilizing quick prototype validation, businesses can not only save costs but also foster innovation.

At Godspeed Design, we understand the critical role that prototyping plays in successful product development. Whether you’re looking to refine your industrial design or optimize your product engineering processes, our expertise in prototype development can help you achieve your goals. Ready to take your product from concept to reality? Contact us today!